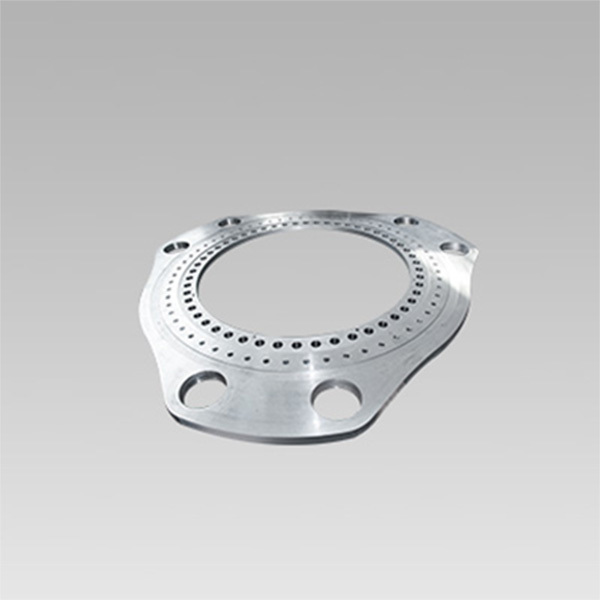

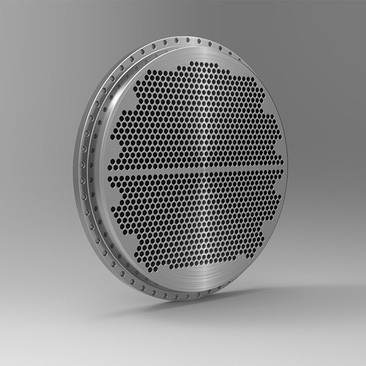

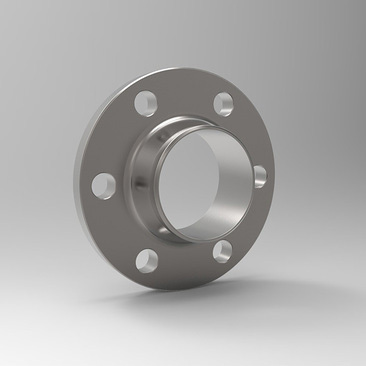

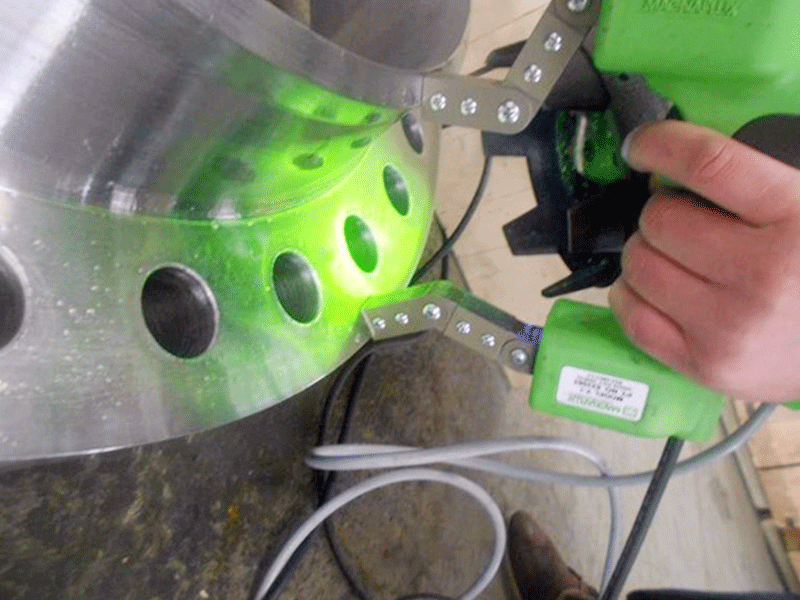

Tube sheet

Factory direct high quality supply integrity and high efficiency quality first

Category:

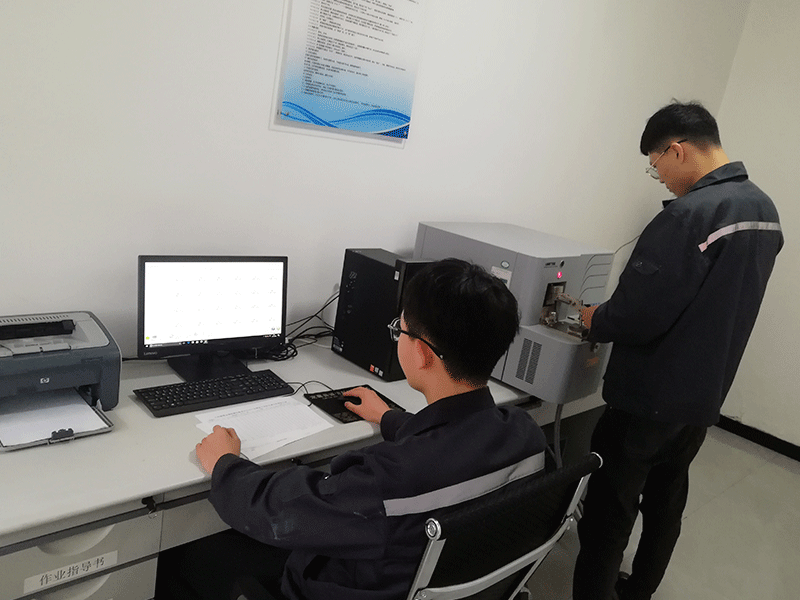

We have always regarded quality as our life, formulated a strict quality control system, and obtained the IS0-9001: 2015 quality management system certificate of TUV NORD company in Germany. With many years of production experience and product quality, it has always been well received by customers in the market.

Product Introduction

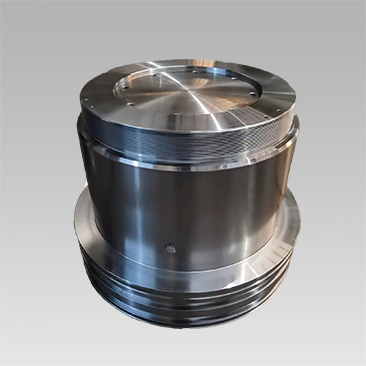

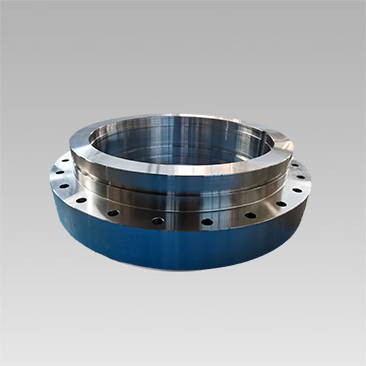

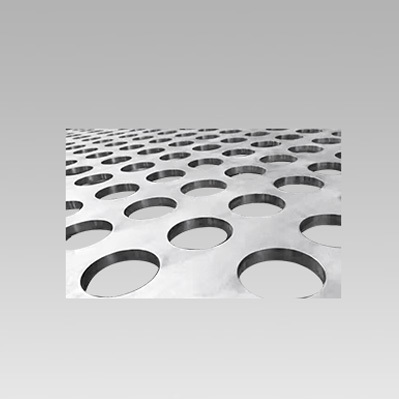

Product introduction:Tubesheet-A round piece of steel used to fix the tubes and seal the heat exchanger. After penetrating into the pipe, the welding strength rises, rises, rises and welds, and other fixing methods are the main accessories in the heat exchanger.

Size:Size 300mm-5000mm, thickness 20mm-500mm weight below 20 tons

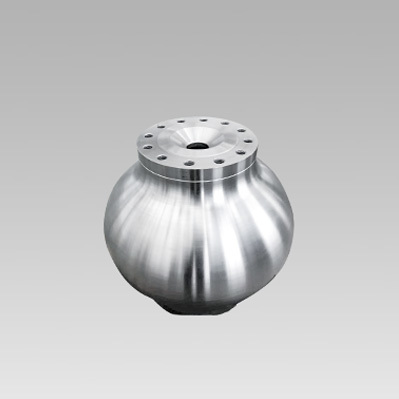

Scope of application:Mainly used in chemical containers, such as tube heat exchangers, pressure vessels, boilers, condensers, central air conditioning, evaporators, seawater desalination, to support the role of fixed tube, metal material not only has a strong rigidity, but also has great thermal conductivity.

Executive standard:Implementation of national standards and customer design requirements

Technical requirements:billet forging heat treatment machining anti-rust treatment

Commonly used materials:Q345E 20MnMo 09MnNiD 15CrMo F316 S304 S321 LF2

The main production equipment includes 1 4000T hydraulic press, 1 10T forging hammer, 1 D53.D52 ring grinding machine, 6 CNC vertical lathe sleeping car CNC drilling center and other machining equipment, totaling more than 80 production equipment.

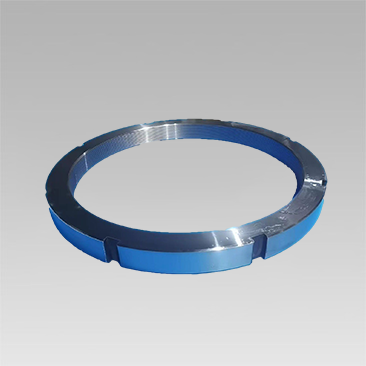

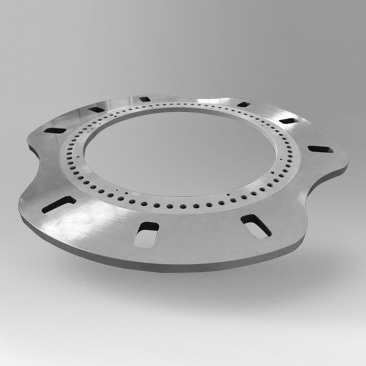

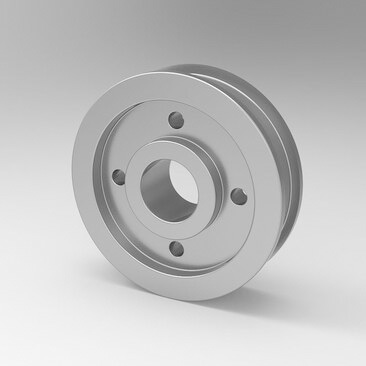

It can produce international, national and industry standard flange tube plate forging products, as well as wind power tower flange yaw brake disc stator pressure ring end cover and other ring forgings can also produce various special-shaped flange tube plate forging products with drawings provided by customers.

We have always regarded quality as our life, formulated a strict quality control system, and obtained the IS0-9001: 2015 quality management system certificate of TUV NORD company in Germany. With many years of production experience and product quality, it has always been well received by customers in the market.

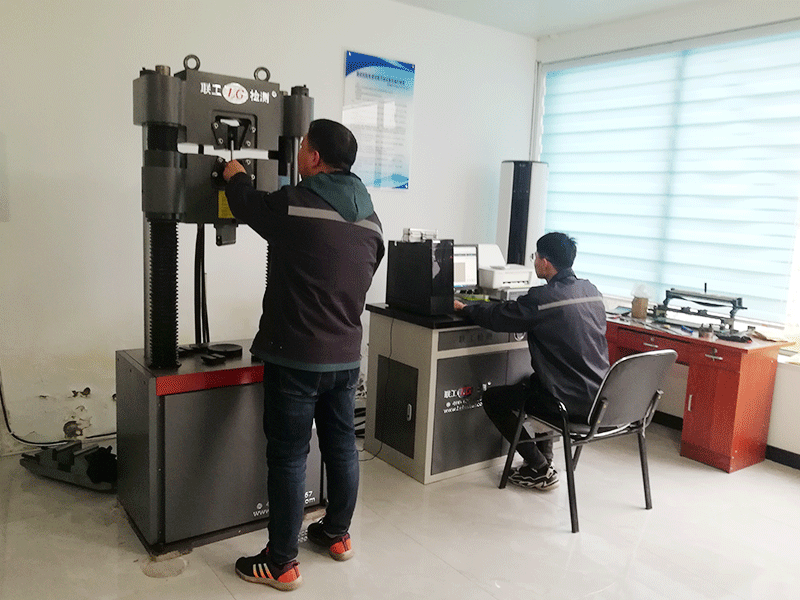

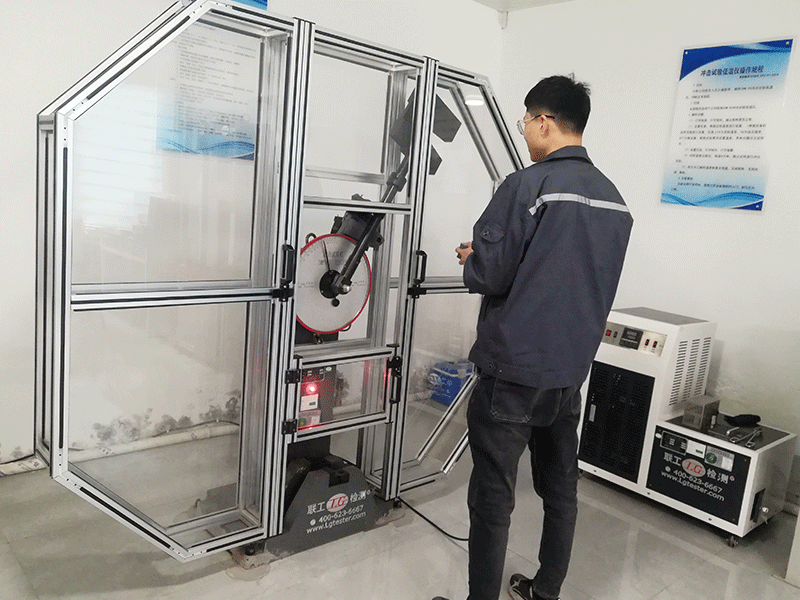

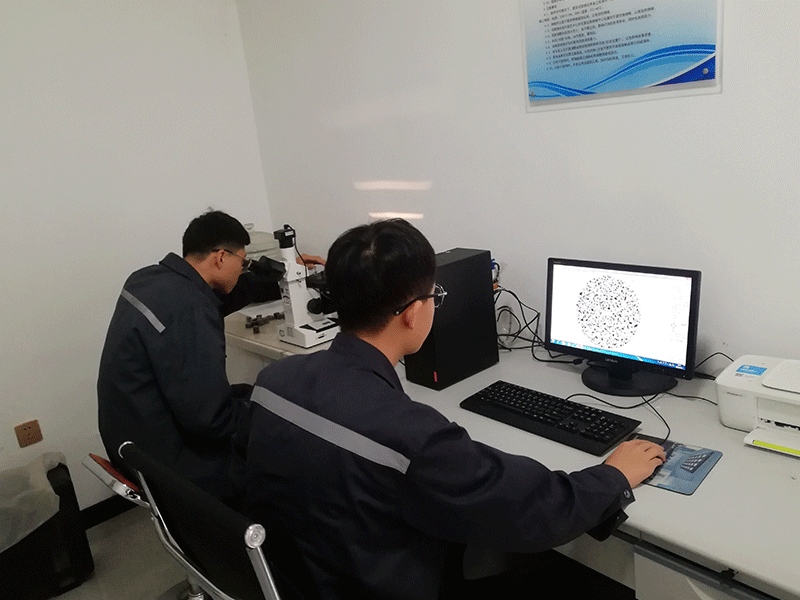

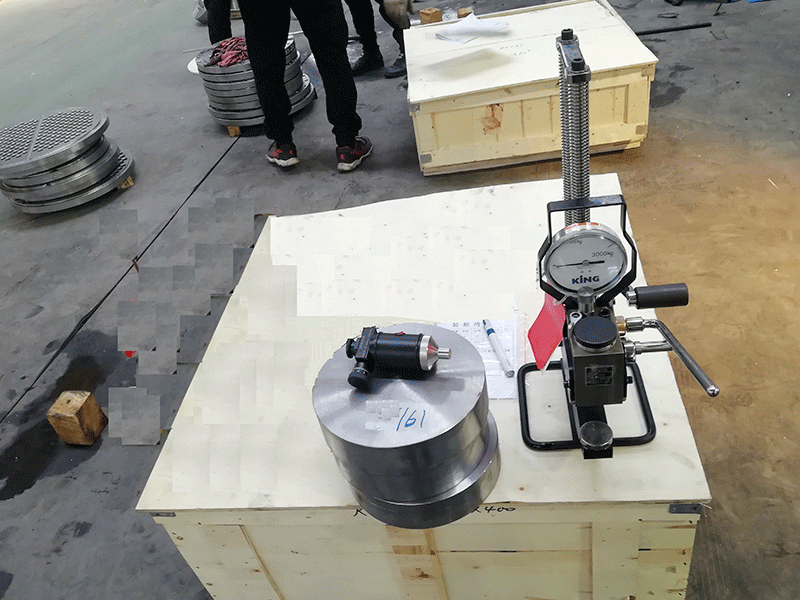

Quality Control

Product Consulting

Related Products